STAGE 1 – DESIGNING

Printer need to have computer with designing software like corel/adobe photoshop / illustrator to make the design which he need to print.

STAGE 2 – POSITIVE MAKING

Printer need Printer like Epson as per size require ( sheet or roll form printer) to make prints of positives required to make screen. Also required RIP software specially for DOT size.

STAGE 3 – SCREEN MAKING

Printer requires screen making machines

Screen stretcher to fix mesh on frame and stretch.

Coater- to coat the coating emulsions on mesh

Screen Dryer- to dry the screen

Exposing- to expose the design with positive

Washing- required washing area to clean and develop the screen

Touching table – required to recheck the design as per positive.

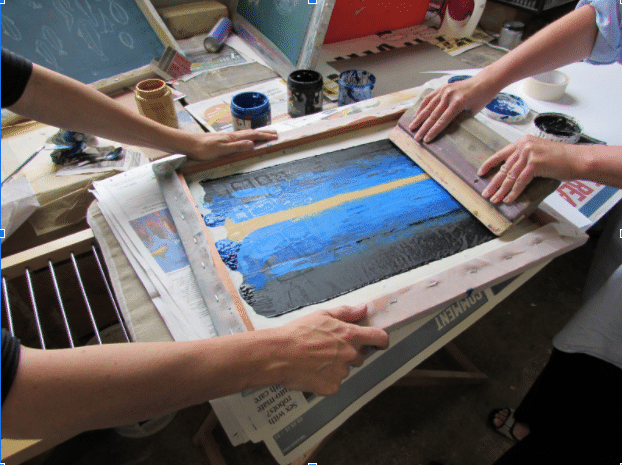

STAGE 4 – SCREEN PRINTING

Printer required Tables/ manual carousel / automatic printing machine as per his quantity and capacity to print on Garment

STAGE 5 – FINISHING ( FUSING/CURING)

Printer required Curing machine to dry the ink on garments. Also, require fusing machine for some application in printing like glossy fusing with paper/ foil fixing/ flock sheet fixing etc.

Printed Garment/Panel is ready.

Ankur Gupta