Tables

Automatic

Starting a screen printing unit involves a combination of equipment, processes, and materials. Here’s a step-by-step guide based on the information you provided:

Understand Printing:

Printing is the process of reproducing text and images using ink on various surfaces.

There are two main types: Screen Printing and Digital Printing.

Types of Printing Machines:

A. Screen Printing:

Manual Tables: Cost-effective for small-scale production.

Manual Carousel: Manual round machine.

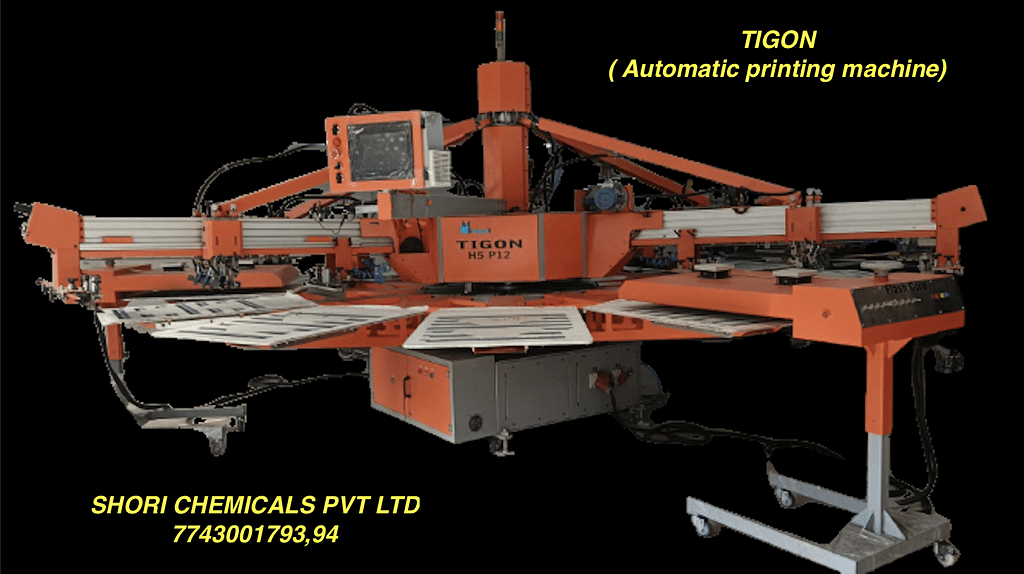

Automatic Round Machine: For higher production efficiency.

Automatic Oval Machine: Specialized for oval designs.

Automatic Flat Bed Vacuum: Used for transfers.

B. Digital Printing:

DTF (Direct to Film)

Plotter

DTG (Direct to Garment)

Sublimation

Sequin/Spangle

Starting Small:

If you have less production or want to test the waters, start with manual tables for cost-effectiveness.

Additional Machines:

Fusing Machine: Used to fix inks to the fabric.

Curing Machine: Ensures proper drying and curing of prints.

Screen Making Unit:

Designer: Knowledge of Corel/Photoshop for creating designs.

Positive Printer: Epson or similar for printing positive films.

Screen Stretching Unit: To stretch mesh onto frames.

Screen Exposure: Exposes the screen with the positive film.

Screen Dryer: Ensures screens are dry and ready for printing.

Types of Inks:

Waterbase, Plastisol Base, Silicon Base, Solvent Base.

Major use nowadays is Waterbase Inks.

Waterbase Inks:

Khadi White Inks/Clear, Pigment – Binder/Fixer/Thickener.

CMYK Process Colors, Neon Fluorescent Shades.

Add-ons like Puff, Jell, Metallic, Pearls, Glitter, Flock, Suede, Beads, etc.

Plastisol Base:

White and other opaque solid colors, CMYK process colors.

Add-ons like Puff, Jell, Metallic, Glitter, Flock, Suede, Beads, etc.

Silicon Base:

White/Clear/Black, Catalyst.

Add-ons like Puff, Jell, Metallic, Glitter, etc.

Solvent Base:

White and other solid colors, Catalyst, Reducer.

CMYK Process Colors, Neon Fluorescent Shades.

General Tips:

Research and invest in quality equipment.

Hire skilled personnel for screen making and printing.

Build relationships with suppliers for inks and materials.

Experiment with different inks and techniques to offer diverse products.

Regulatory Compliance:

Check local regulations and comply with safety and environmental standards.

Remember to adapt this guide based on the scale of your operation and specific market needs. Continuous learning and staying updated with industry trends are essential for success in the printing business.

for more details discussion, please feel free to contact

ANKUR GUPTA

(md)

SHORI CHEMICALS PVT LTD

wa.me/919814078818

Check my youtube channel