Got Questions? Call Now

- 9814078818

- Email: info@shorichemicals.com

5 secrets to Increase your revenue and profits in Garment screen printing

- Are you facing problem of productions in screen printing?

- Are you facing problem of Quality in screen printing ?

- Are you getting problem of Variation in screen printing ?

- Are you facing problem of getting efficiency from workers?

- Are you facing problem in getting Fine prints on Tables?

- Are you facing problem of High Labour cost in printing?

- Are you facing problem of finding skilled Labour?

- Are you Facing problem of producing same quality for big productions?

5 SECRETS

1. AUTOMIZATION

Automisation is One of the most important secret to increase the revenue. Dependency on Labour and buying or renting long and big land can be easily replaced by Automatic machine.

Buy INDIAN Grafica Automatic screen printing machine since this is only machine in world which is cheapest and with all features in Automatic machine against Expensive imported ones.

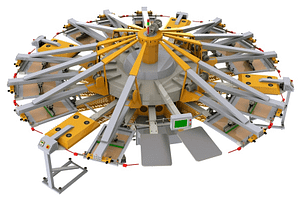

Round Automatic screen printing machine

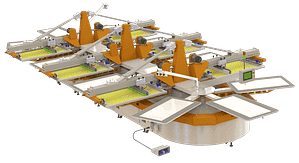

Oval Automatic screen printing machine

6 Advantages of buying Automatic machines over conventional Table printing:

- a. 50% less Investment with less space in land and construction over manual screen printing unit.

b. High production

c. Consistent Quality in printing

d. Saves labours cost

e. less number of Labour for printing

f. 20% saving in Ink consumption

g. More Efficiency of Labour.

You can click on link to know more about Grafica Automatic screen printing machine models.

You can download and select the machine on the following basis:-

A. Maximum print area you want to print.

B. Number of maximum colors you required.

2. COST CALCULATION

Until you know the exact cost of job, how can you take profit?

As per my knowledge, normal trend in market is to quote the price of job as per market price.

You should calculate your cost price per job as per your own factory, not market. If you have different expense, how can the costing be same for everyone.

For each and every production, you should make the cost sheet to calculate the costing individually of ink consumed, screen cost, labour cost. I am giving you link to download JOB SHEET FORMAT, COST ESTIMATOR OF INK AS PER JOB . This will help you to know what is your cost and you can accordingly quote the price.

3. DIFFERENT TECHNIQUES WITH NEW AND OLD INKS

Giving new creations is easy way to earn and charge more in printing.

Since printing on garment is directly link with new designing and how to use old ink in new design, there is always scope of new creation.

I am providing you link for my book in which I have mention as

“21 Techniques you may have missed in Textile screen printing”

You can buy and always design something new.

4. USE OF STANDARD AND BRANDED PRODUCTS

I recommend to use standard and branded products which helps in meeting quality standard and increasing revenue.

The ones who keep changing products to find cheaper options don’t get stability in printing.

Fix your requirement and standards.

Here is link for our standard and branded product range of inks and chemicals used screen printing.

5. ADOPTION OF LATEST MACHINERY AND ITS USAGE

You can use Digital and Transfer application to make unique combination.

You require DTG machine with transfer technology to create unique designs.

Combination can be as follows:-

- SCREEN + DIGITAL

- SCREEN + PLOTTER

- SCREEN + EMBRODIERY

- SCREEN + LASER PATCH

- SCREEN + TRANSFERS(SCREEN)

- SCREEN + SUBLIMATION PATCH

- DTG + PLOTTER

and many more

New creation is easy way to earn more.

Our Strengths

Consistent Quality

Standard Packing

New Products

Eco-Friendly

Timely Supply

Testimonals

WHAT OUR CLIENTS SAYS

Janaksons Knitwear Pvt limited

" Quality of product as per satisfaction with fast delivery"

Rishi Printing Pvt Ltd ( Flicker Hood)

"Fully Satisfied with services of Shori chemicals with Full Technical Support"

Addonz

"Consistent quality with new innovication for last so many years"

Usha printing

" Trust blindly Shori chemicals for what they say and what they deliver"